By harnessing the latest, innovative, and cutting-edge technologies, the mass production of the world’s first sustainable tyres has become a reality, and reTyre is proud to be able to integrate different emerging technologies from various industries into our tyre production.

We hold great appreciation and respect for the pioneers whose innovations have reshaped manufacturing over the centuries. This article explores the historical progression of industrial revolutions that have laid the foundation for the technological advancements we see today.

Revolutionising Manufacturing: From Assembly Lines to Smart Factories

This work is licensed under CC BY-ND 4.0

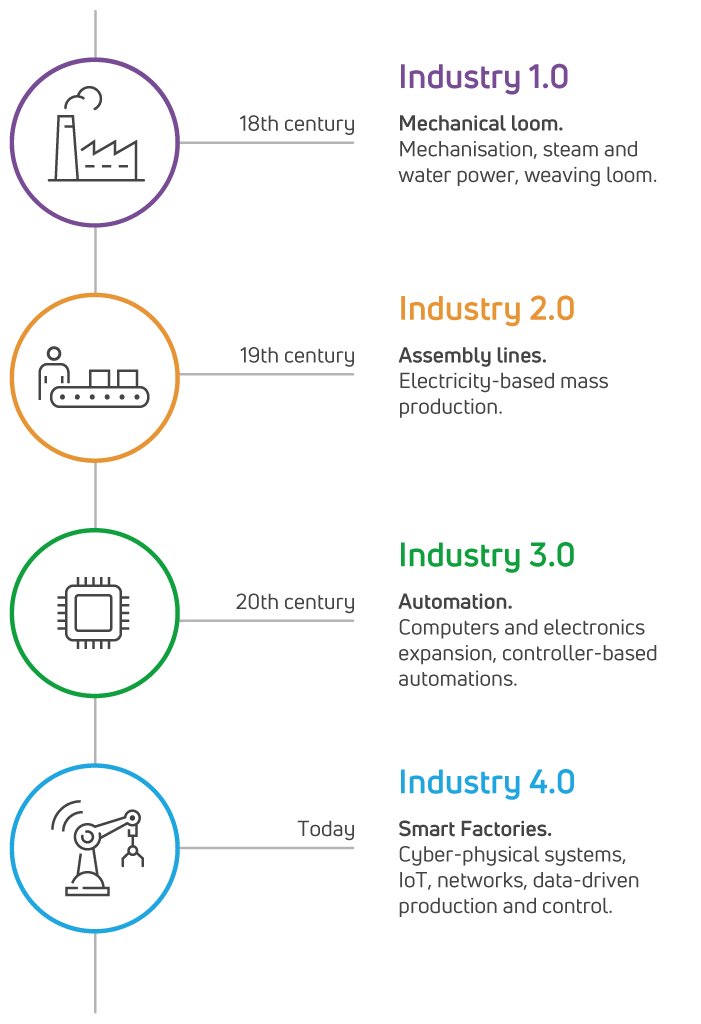

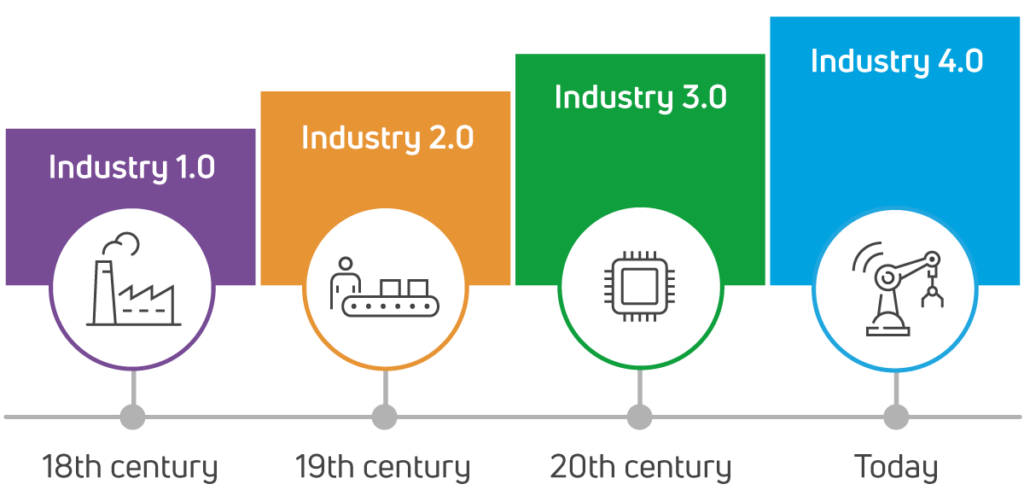

The journey of industrial evolution is a testament to human ingenuity and technological advancement. From the inception of mechanical production facilities powered by water and steam to the electrification of manufacturing processes, through the introduction of automation, and now to the dawn of cyber-physical systems, each industrial revolution has significantly altered the landscape of production and manufacturing.

Historical Shifts in Manufacturing

The First Industrial Revolution (Industry 1.0)

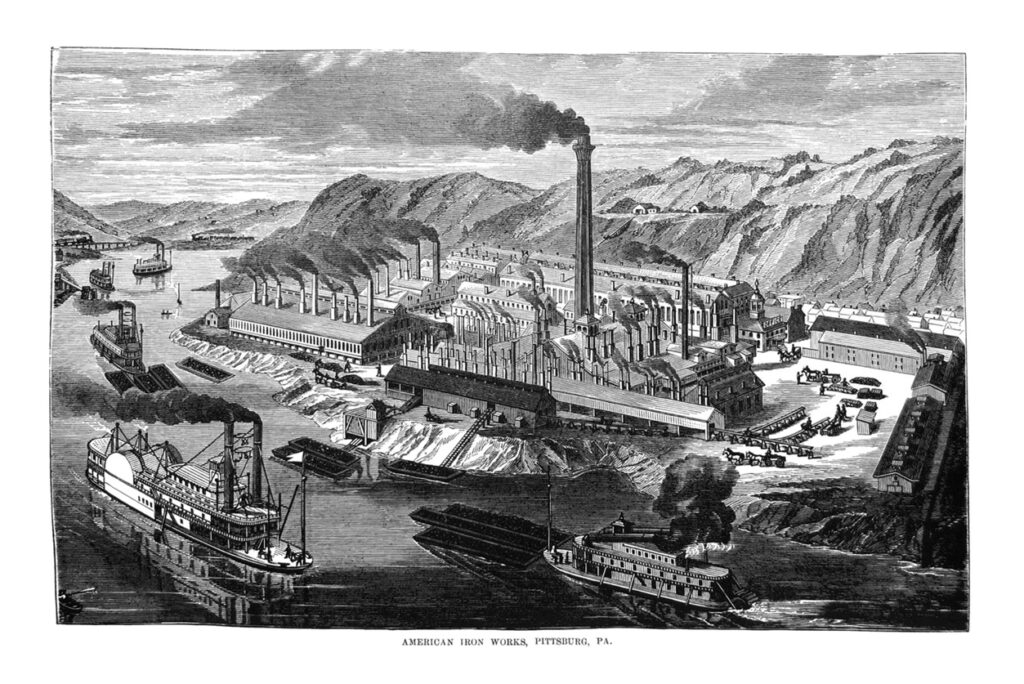

The first industrial revolution, which began in the late 18th century, marked a pivotal shift from agrarian societies to industrial powerhouses. The introduction of the steam engine enabled the mechanization of labor, leading to the establishment of factories and the beginning of mass production. This era’s hallmark was the transition from hand production methods to machines and the rise of the textile industry as a model of this new manufacturing paradigm.

- Transition from manual labor to mechanised production

- Introduced machines powered by water and steam

- Laid the groundwork for the modern manufacturing sector enabling the production of goods on a scale previously unimaginable

- However, was also characterised by labor-intensive processes and low efficiency (by today’s standards).

The Second Industrial Revolution (Industry 2.0)

Building on the mechanical innovations of the first industrial revolution, the second revolution, which took off in the late 19th century, was characterised by mass production and the introduction of electricity. The development of the assembly line by Henry Ford in the early 20th century optimised this era, drastically increasing production rates and efficiency. This period also saw significant advancements in steel production, chemicals, and electrical engineering, laying the groundwork for modern industries.

- The introduction of electricity, railroads, and telegraph lines

- Introduction of the assembly line by Henry Ford

- Mass production of goods

- Significant reduction of cost of goods

- Rise of industries such as steel, oil, and electricity

- Rapid industrialisation of societies

- New levels of productivity and efficiency

The Third Industrial Revolution (Industry 3.0)

The third industrial revolution, emerging in the late 20th century, was marked by the digital revolution and the introduction of computers and (semi-, partial- or controller based-) automation into the manufacturing process. This era saw the development of electronics, telecommunications, and computers, fundamentally changing the way products were manufactured and services delivered. Automation became a key feature of production lines, enhancing precision and productivity while reducing human error. Robotic and automated solutions started taking over tasks that once required manual effort, improving accuracy and enabling uninterrupted production workflows. Key features also included the growth of e-commerce, social media, and digital entertainment, along with the advent of innovative manufacturing techniques like 3D printing.

- Digitalisation, automations, and computer-aided manufacturing

- Robots and automated systems replacing manual labor

- Enhanced precision and continuous production cycles

- Rise of the internet and digital technologies creating new business models

- Industries adopting electronics and information technology to further improve efficiency and productivity.

The Fourth Industrial Revolution (Industry 4.0)

Now, we find ourselves in the midst of the fourth industrial revolution, characterised by the fusion of technologies blurring the lines between the physical, digital, and biological spheres. Cyber-physical systems, the Internet of Things (IoT), big data, and artificial intelligence (AI) are at the heart of this transformation.

Industry 4.0 represents a paradigm shift in manufacturing, characterised by the integration of digital technologies into all aspects of production. The core of this revolution is the smart factory, where machines can analyse and diagnose issues without human intervention. The cyber-physical systems monitor physical processes, create a virtual copy of the physical world, and make decentralised decisions. Through the Internet of Things (IoT), big data analytics, and artificial intelligence (AI), Industry 4.0 enables:

- Predictive Maintenance: Anticipating machinery failures before they happen, reducing downtime and maintenance costs.

- Enhanced Efficiency: Optimising production processes in real-time for maximum efficiency and reduced waste.

- Customisation: Enabling mass customisation of products to meet individual customer requirements without sacrificing efficiency.

This revolution offers unprecedented opportunities for customisation and flexibility in production processes.

As we continue to navigate the complexities of Industry 4.0, it’s clear that the future of manufacturing lies in the integration of smart technologies, heralding a new era of innovation and productivity. Understanding the history and features of these industrial revolutions not only provides insight into our past but also illuminates the path toward a more interconnected and technologically advanced future.

From Steam to AI

This work is licensed under CC BY-ND 4.0

Each industrial revolution has been defined by the main features of its time:

- Industry 1.0: Mechanisation, water and steam power.

- Industry 2.0: Mass production, assembly lines, electricity.

- Industry 3.0: Automation, computers, and electronics.

- Industry 4.0: Cyber-physical systems, IoT, big data, AI.

The evolution of industrial revolutions has dramatically transformed manufacturing, from the steam-powered factories of the 18th century to the smart factories of today. This evolution showcases humanity’s relentless pursuit of technological advancement and efficiency. From the steam engine to cyber-physical systems, each era has significantly impacted how we produce goods and services.

The leap from each revolution to the next has been characterised by an increase in efficiency, productivity, and the ability to scale manufacturing processes. However, the most significant differentiation of Industry 4.0 is its focus on interconnectivity and intelligence, providing a level of data analysis and machine learning capability that allows for more sustainable, efficient, and customisable production processes.

At reTyre, we’re actively engaged in this journey, especially with the new developments on the AI front. Our commitment to incorporating the latest and greatest of emerging technologies into our operations ensures that reTyre continues to lead the way in producing sustainable and innovative tyre solutions, setting new standards for the industry.

Stay tuned for the environmental impacts of the industrial revolutions (the second part is coming soon).

Resources

https://en.wikipedia.org/wiki/Industrial_Revolution

https://www.thoughtco.com/textile-machinery-industrial-revolution-4076291

https://www.britannica.com/event/Industrial-Revolution/The-first-Industrial-Revolution

https://en.wikipedia.org/wiki/Second_Industrial_Revolution

https://faculty.wcas.northwestern.edu/jmokyr/castronovo.pdf

https://www.thoughtco.com/second-industrial-revolution-overview-5180514

https://stefanini.com/en/insights/news/the-role-of-automation-in-digital-manufacturing-advantages-and-applications

https://www.linkedin.com/pulse/industrial-revolution-30-zeekoi/

https://upkeep.com/learning/industry-3-0-vs-industry-4-0/

https://www.weforum.org/agenda/2016/01/the-fourth-industrial-revolution-what-it-means-and-how-to-respond/