BIO-BASED

Reusable Elastomers

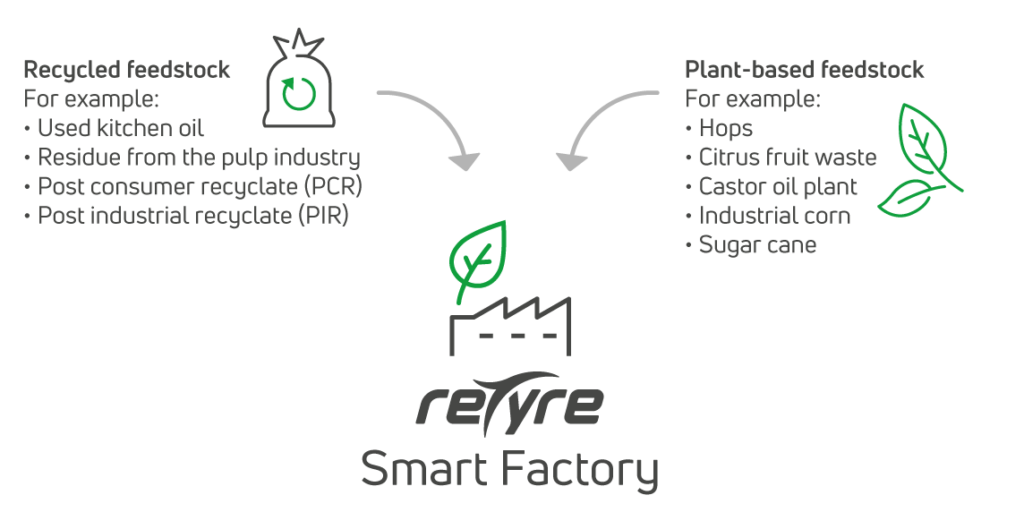

Our production method gives us access to a wide range of materials previously unavailable for pneumatic tyres. With our expertise in sourcing, we’re not merely choosing materials off a shelf; we’re meticulously selecting the right materials tailored for specific vehicles, enhancing performance, safety and product design.

We set new product standards for the industry, also in terms of reduced emissions. reTyre is not just shaping the future of tyre manufacturing; we are leading a paradigm shift towards more efficient, safer, and environmentally friendly industrial practices.

All our tyres are more sustainable compared to conventional vulcanised tyres, since every material we use will reduce the emissions.

REDUCE YOUR EMISSIONs

In the latest life cycle assessment (LCA) we achieved a significant CO2 reduction of 82%1.

At this point, we want to highlight, that our material is the only factor left in the LCA which influences the emissions. This gives us full control over CO2 just by material selection.

Feel free to contact us for more information!

1 reTyre AS. Comparative life cycle analysis. 2024. (based on: Emilce Romarion & Vijay Thakur. Products: Conventional Bike Tyre & ReTyre. Comparative life cycle analysis. Intertek. November 2023.)