ONE STEP AHEAD OF ENVIRONMENTAL GOALS

reTyre provides detailed LCAs for all products

reTyre, as a pioneering manufacturer of sustainable tyres, recognises that accurate and reliable data plays a key role in successfully reducing environmental impact.

That is why we provide our customers with precise data to enhance their Environmental, Social, and Governance (ESG) reporting. By collaborating with Intertek Deutschland GmbH we ensure the quality of the data and compliance with international standards.

Third-party-verified by:

In March 2024 and in compliance with ISO14040 & ISO14044, an independent critical review panel consisting of 3 external verifiers that are considered experts in the field of LCA reviewed and approved the “Conventional Bicycle Tyre vs reTyre” LCA report that was developed by Intertek Assuris dba Intertek Deutschland GmbH and reTyre over the course of 9 months.

Emission data for all tyre sizes

UNTIL THE END-OF-LIFE

Cradle-to-cradle approach

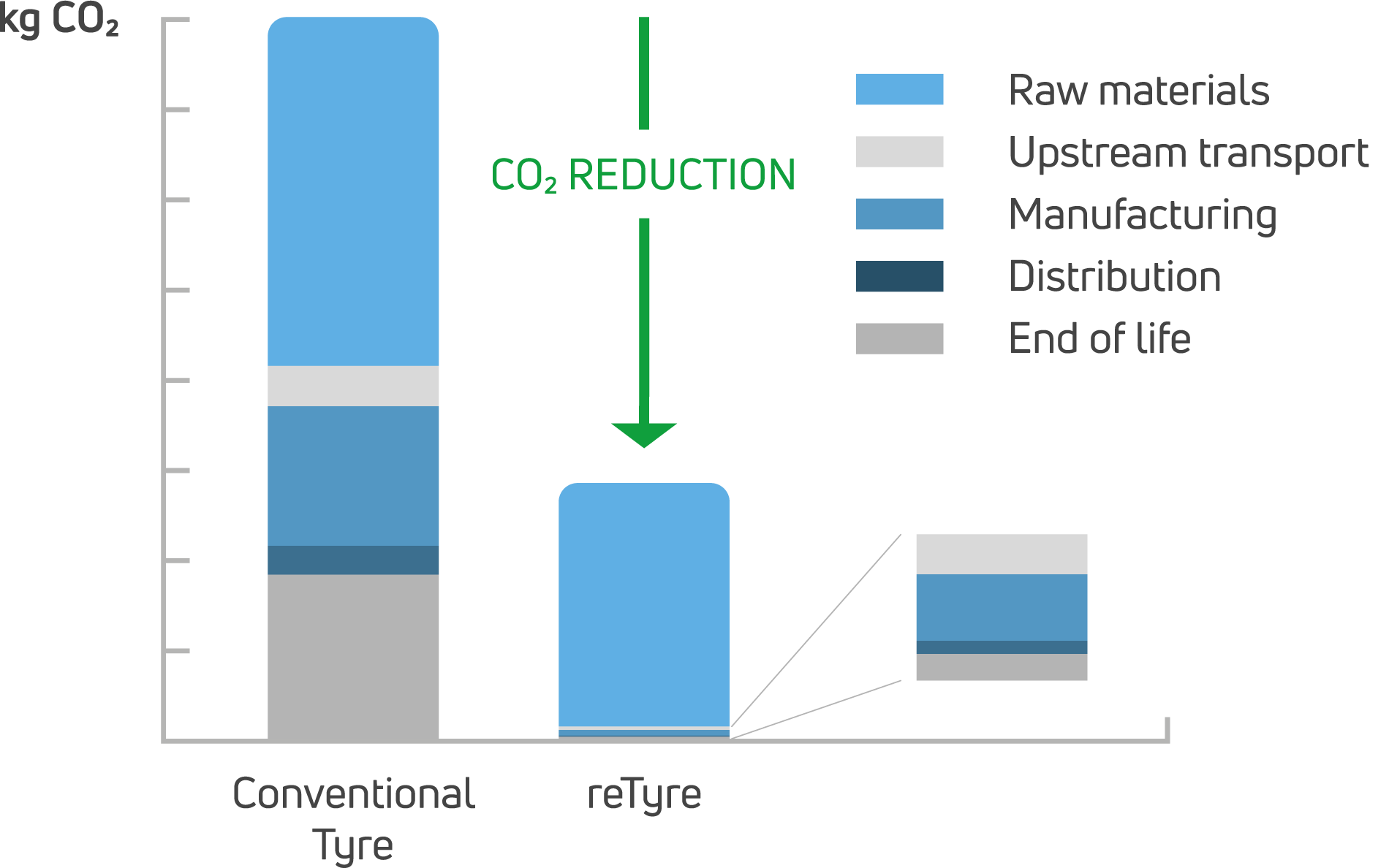

reTyre is using the Cradle-to-cradle approach. This approach considers the entire life cycle of a product or service, including the extraction of raw materials, production, use, and disposal/recycling into a possible next life cycle. The goal is to create closed-loop systems where waste is minimised and materials are continuously reused.

In contrast, the cradle-to-gate approach (often used by our competitors) only considers the environmental impact from the extraction of raw materials through the production stage, up until the product leaves the factory gate. It does not include the downstream stages of transportation, use, and end-of-life.

Scientific Foundation

-82% CO2 Emissions

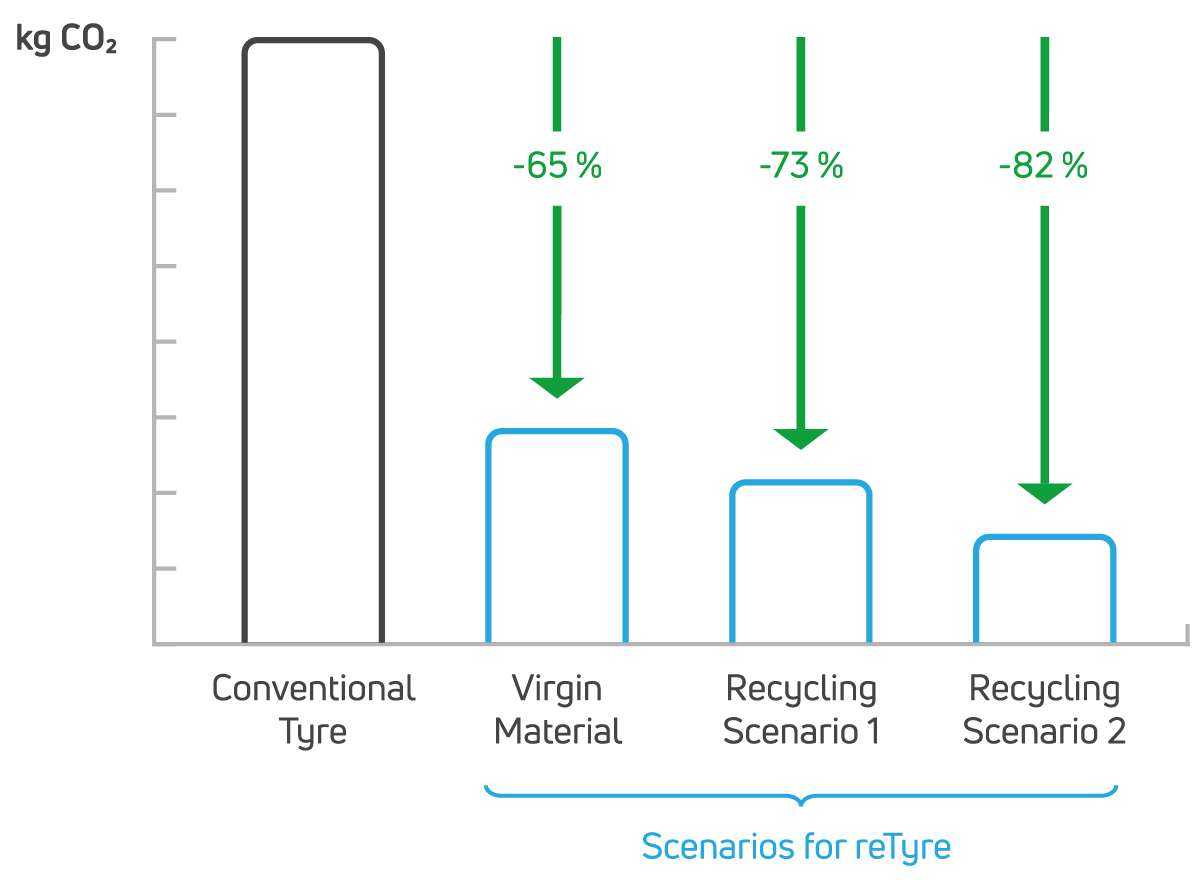

Our Life Cycle Assessment (LCA) shows the superior environmental benefits of reTyre products. The studies also show the impact of the Conventional tyre, reinforcing the importance of sustainable material choices and innovative design in reducing the environmental impacts of consumer products.

To create an LCA, as for any scientific discipline, building on existing peer-reviewed studies is necessary. In the field of bicycle tyres, only one(!) such study, Lin et.al. (2016) was deemed acceptable by Intertek Deutschland GmbH to be in compliance with the LCA ISO framework. The Lin et.al. (2016) article was therefore chosen as the scientific foundation for the CO2 numbers provided for the Conventional tyre.

Key findings

1) Global Warming Potential (GWP) impact: The study finds that reTyre significantly reduces GWP across its lifecycle. Specifically, reTyre showcases an impressive reduction in GWP by up to 82% depending on the degree of recycled Thermoplastic Elastomers (TPE) compound used in manufacturing.

2) End-of-Life Advantages: reTyre’s design for recyclability plays a crucial role in its environmental performance, contributing to minimal impacts at the end-of-life stage. The Conventional tyre has a more significant end-of-life impact due to energy recovery (incineration), and landfill disposal. Just by replacing conventional materials with elastomers (Virgin Material), the CO₂-equivalent will be reduced by 65%. If the virgin elastomers are replaced with recycled material, the CO₂ reduction achieved will be even better, with reductions of 73% in Scenario 1 and 82% in Scenario 2.

3) Additional scenarios: The study also discusses scenarios where advancements in reTyre technology, such as the development of a partially foamed tread, could offer further environmental benefits, enhancing the tyre’s sustainability profile. The study also offers scenarios with the utilisation of the mass balance approach.

Data-Gathering

In compliance with ISO 14040 and 14044, data is gathered directly from the source (e.g. the supplier of a TPE compound material), while other data is gathered from a global database (i.e. ecoinvent) where a certain material has a certain CO2-equivalent impact. Multiple factors throughout a product’s life cycle must be included and thus gathered data for. Detailed data sources are provided in the LCA for individual products.