The environmental costs of rubber tyres and how new materials promise to improve this

Rubber has changed the world for good and bad. Its use in tyres is still essential to keep us all moving, but it has a history of environmental and social damage, in all stages of its farming production, use and disposal.

While a number of initiatives are trying to reduce rubber’s footprint, it may be that alternative materials are the only way to really ‘green’ the tyre industry.

In this article, we will look at how rubber became such an important feature of the modern world, the environmental costs that brought with it, and new technology that could revolutionise the way we produce tyres. You can find the following topics:

- History of rubber

- Natural vs Synthetic

- Impact of rubber

- CO2 footprint of rubber

- Microplastics and particulates

- Disposing

- A new way for tyres

What are rubber tyres made of?

A history of rubber production

Rubber has a long history and was first brought to European attention by Christopher Columbus who discovered the Maya people were using it to make toys. However, it wasn’t until the 19th century that its unique properties really began to find a use in the industrialising world.

Charles Goodyear discovered that, mixed with a little sulphur, rubber vulcanised and became much stronger and less sticky. Soon the shock absorbent potential of rubber was being applied to making wheeled transportation more comfortable. In 1888 John Boyd Dunlop received a patent for the first pneumatic tyre, an invention that quickly proved its worth, winning several bicycle races.

While rubber was discovered and first farmed in South America, it is Southeast Asia where most of the world’s rubber plantations were established. This typically colonial industry paid scant regard to the needs of local peoples and ecosystems as it fed an ever-growing demand for tyres.

What Rubber Tyres are made of now

Currently, natural rubber is still used in nearly all auto tyres, but synthetic rubber has also become a major ingredient.

In 1909 German chemist Fritz Hofmann, working for the German chemical company Bayer, invented the first commercial synthetic rubber. Not long after it started being used in car tyres, a process that was intensified during the second world war as supply lines to plantations were threatened.

Today most car tyres contain synthetic rubber and natural rubber (typically about 19 percent natural rubber and 24 percent synthetic rubber) with the rest made up of metal and other compounds.

The environmental and social impact of rubber

The farming and production of natural rubber has had a devastating impact on the environment with large forest clearances to create plantations. These usually become mono-cultures, degrading the habitat and soil and polluting the local environment with the use of chemicals. Socially too the plantations have a terrible track record that includes the use of slave labour and still see local farmers and labourers underpaid to this day.

The competition between relatively small-scale growers and the instability of global rubber prices are some of the factors that afflict these farmers. Poor education is another. Overall, it is a sector where change is hard and renewable and sustainable solutions are only slowly being realised. The World Wildlife Fund is at the forefront of efforts to improve this and has succeeded in getting some big-name tyre manufacturers to sign up to the WWF initiative on sustainable rubber production. However, there is still a long way to go.

Meanwhile, the demand for rubber only grows. Since 1990, global rubber production has trebled with more than 70% of that going into making tyres.

The CO2 impact of rubber

As we’ve already seen, modern tyres are made up of a mix of natural and synthetic rubbers. The synthetic materials in your average car tyre require about 7 gallons of oil to make, while a truck tyres take 22 gallons.

Synthetic rubber production has a significant environmental impact due to the use of petrochemicals, energy-intensive processes, and the generation of hazardous waste. Some estimates suggest that the production of one ton of synthetic rubber can generate more than 2.5 tons of CO2 equivalent emissions.

The CO2 impact of car tyres is further exacerbated by the energy mix in some of the countries where natural rubber is treated. Many of the plants in South East Asia are powered by relatively ‘dirty’ energy such as coal.

However, the environmental impact of tyres does not end with their production. Their usage and disposal also have an impact:

Worse than exhaust fumes and plastic bags? The impact of microplastics and particulates from rubber tyres

The environmental implications of tyre wear are only recently becoming fully understood or receiving the attention they deserve. This is in part because other auto-pollutants are declining with modern cars becoming more efficient, less polluting or fully electric. It is also because modern cars, especially electric ones are getting heavier and causing more tyre wear as a consequence.

It has been estimated that a third or more of all microplastics found in the ocean come from tyres, damaging aquatic life and ecosystems. Amazingly, this all comes from the friction between rubber and road as a tyre degrades over time.

Tyre wear on road surfaces is also an issue in local air pollution as tiny carcinogens are thrown into the air. These particulates can get deep into our lungs and be very dangerous for human health. Extraordinarily, the Guardian recently reported that car tyre wear may already be a bigger local air polluter than exhaust emissions.

Disposing of rubber tyres: when recycling isn’t so green

Rubber tyres are not biodegradable and every year 1.5 billion come to the end of their useful life (this includes tyres that have been re-treaded, and worn out again). There are some positive trends with the recycling of tire scraps into products such as playgrounds, sports fields, and even roads and pavements (have you noticed your pavements getting bouncier?) Also, many fewer tyres going to landfills than in the past.

However, a great many old tyres are burned to generate energy, releasing lots of carbon dioxide into the atmosphere along with a number of toxic pollutants such as zinc and chlorine. This counts as recycling in published figures and contributes to claims by the industry that upwards of 90% of ‘end of life’ tyres are recycled.

Whether this is really good for the environment depends on the type of incinerator used and how the emissions are managed. Many incinerators are located in poorer countries (including some that have been exploited for decades in the rubber trade), where standards in emission control may not be so exacting. So, while using old tyres to fuel power generation sounds like an environmental win, the reality is often less positive. Many Western countries ship large quantities of old tyres to poorer countries where they are burned in sub-optimal plants, releasing toxins into the local environment. These tyres are then counted as ‘recycled’ waste in their official figures.

A new way for tyres. 0% rubber in our tyres

While there are initiatives to clean up the rubber industry, it remains a very substantial polluter. Few if any of the solutions thus far have challenged the basic orthodoxy that tyres are produced from a mixture of natural and synthetic rubber.

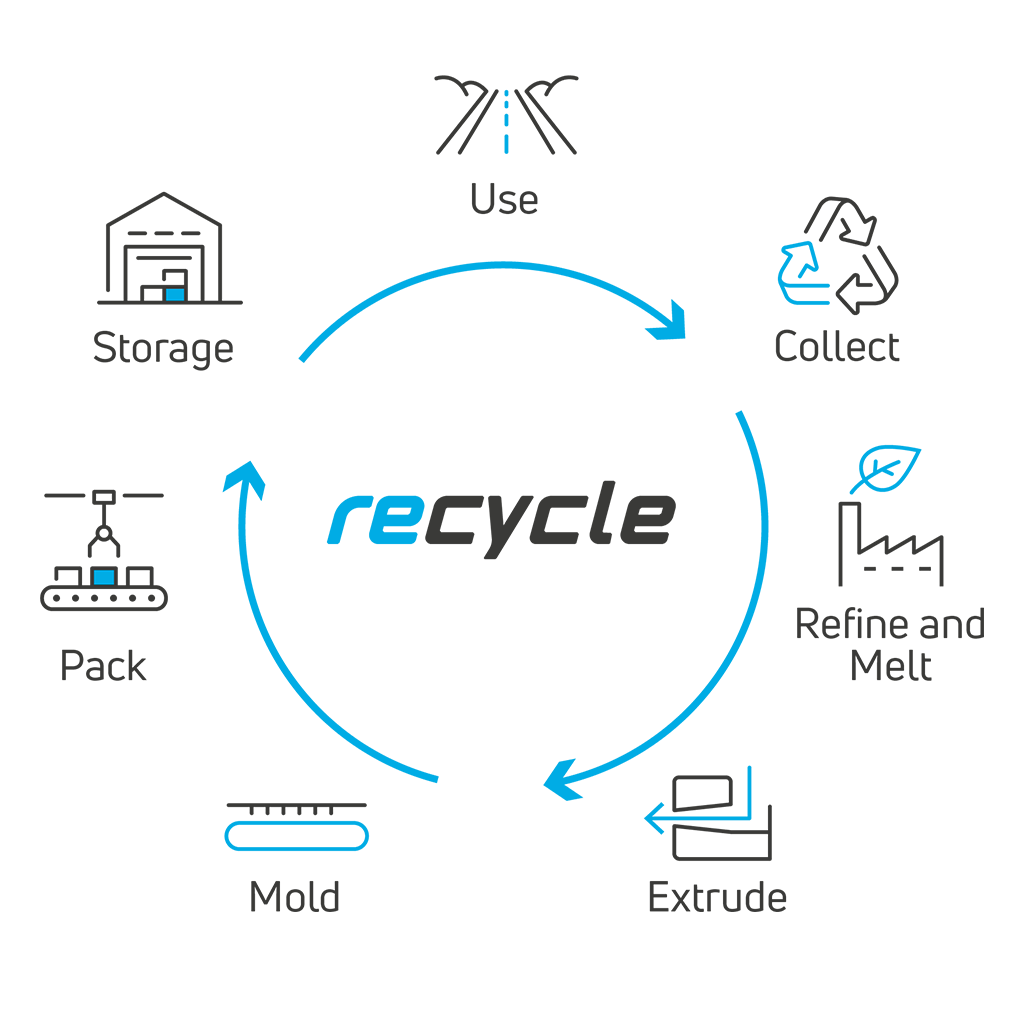

This is set to change. After more than eight years of experience with innovative tyre solutions, reTyre is producing the most sustainable tyres in history – by all measures. By use of new materials, more energy efficient and precise manufacturing and local production reTyre is able to reduce GHG emissions and produce 100% reusable tyres.

What’s more, the finished product promises to produce tyres of good or better quality than current production norms.

If this sounds too good to be true, well it isn’t.